Design for Recycling

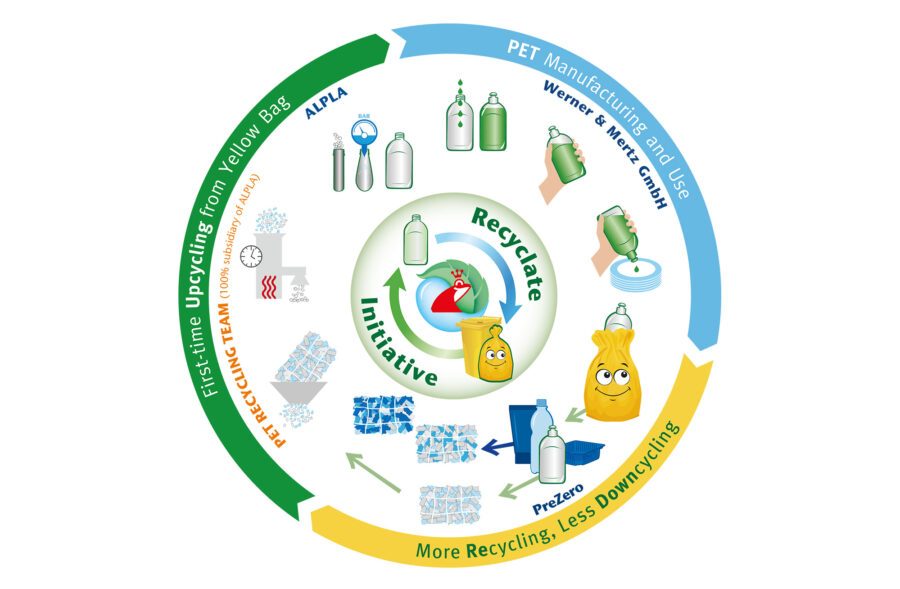

The Recyclate Initiative from Werner & Mertz promotes high-quality mechanical recycling of used plastic from household waste collections like the Yellow Bag in order to close loops and actively contribute to climate protection.

Why it’s important to see used plastic as an important resource and to keep it in a climate-friendly closed loop is made apparent by the numbers from the Plastic Atlas issued by the Heinrich-Böll-Stiftung:

“Between 1950 and 2015, about 8.3 billion tonnes of plastic were produced around the world—nearly half of that since the year 2000. One-way products and packaging make up the vast majority. Not even 10 percent of all the plastic ever produced has been recycled—in Germany the figure was just 15.6 percent in 2017. If plastic production continues at this pace, plastic alone will have generated about 56 gigatonnes of CO2 emissions by the year 2050. That means plastics would be responsible for between 10 to 13 percent of the remaining CO2 budget for the 1.5-degree target.”

Recycling the way Nature shows us

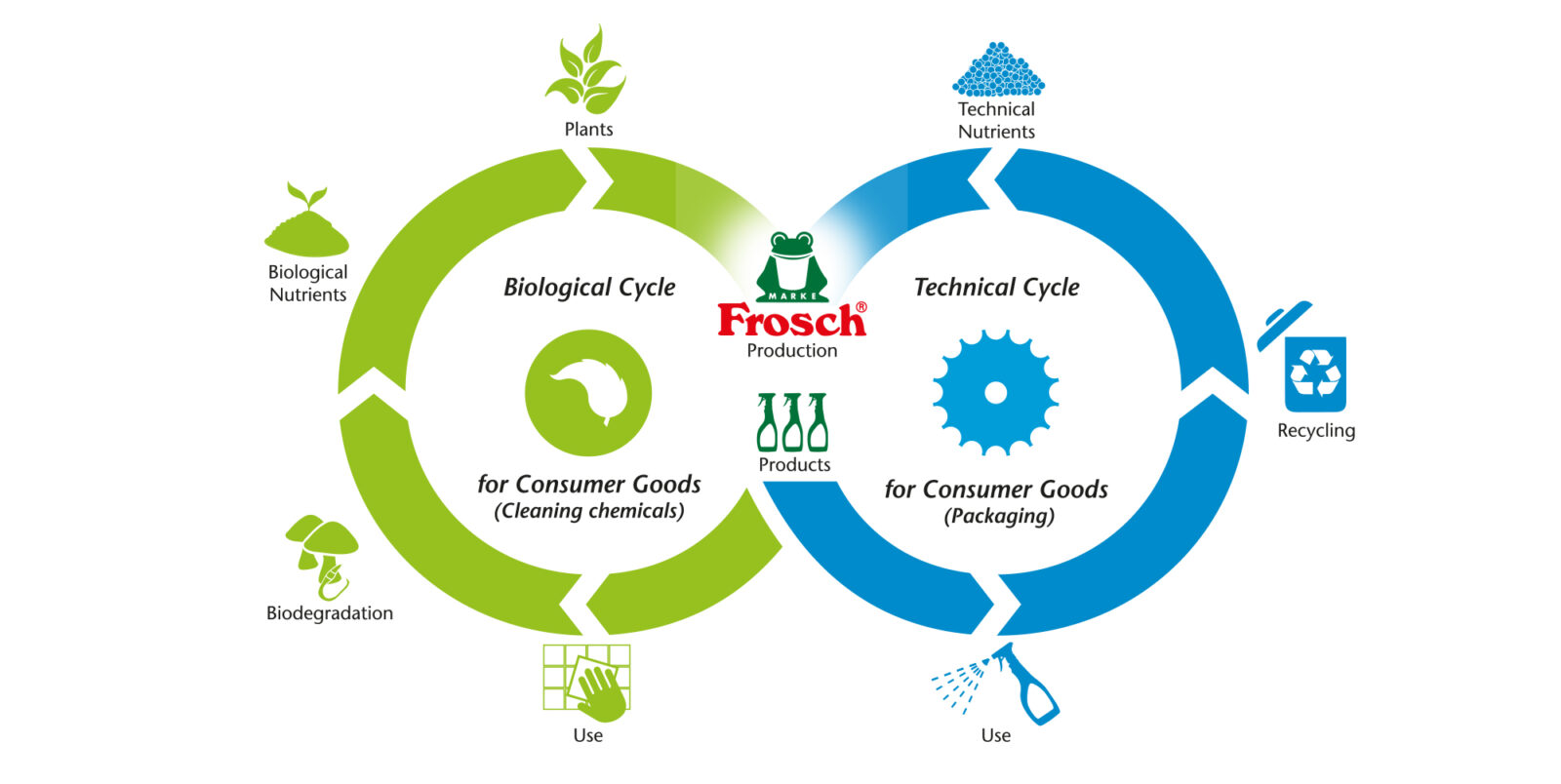

Our initiative conforms to the Cradle-to-Cradle Principle, developed at the end of the 1990s by the German chemistry professor Dr. Michael Braungart and the US American architect William McDonough. The principle is modeled after processes in Nature in that there is no such thing as waste. Instead, every end product functions as nutrients for something new.

The raw materials required for production are developed in such a way that they can be kept in biological and technical cycles. That makes the materials suitable for a safe and complete return to the biosphere or for recovery and good quality reuse. The Recyclate Initiative takes up this concept and develops processes for the recycling of plastic waste.

The design comes first

Frequently, the thought process begins at the end when plastic products and plastic packaging have served their purpose. In many countries around the world, attention is given to important steps such as improving waste collection, closing gaps in the systems and making recycling more environmentally friendly. But all that comes at the end of the problem. In the long run, it is much more effective to think about recycling at the start, when products and packaging are designed, when decisions are made about the materials and quantities to be used. At that point, a choice is made about whether to use one type of plastic or a mix of completely different, inseparably bonded materials. All these considerations during early design phases determine whether a product or packaging can be recycled after its useful life instead of being thrown away.

A product’s shape, purity of materials, types of connection (screwed, inserted, glued, etc.), labeling and other details have far-reaching consequences for its recyclability. In general, the more complex a product is, the greater the recycling effort. It is not possible to recycle used products economically if they consist of a large material mix of inseparable types of plastics, if their caps and similar parts have been welded, or if their labels are not completely removable.

Therefore, the Recyclate Initiative from Werner & Mertz promotes the development of recycling-friendly designs for packaging materials and product packaging – a process referred to as “Design for Recycling”.

The circular economy gets waste prevention going

The world’s plastic industry has to adhere to the principle of recycling within a circular economy in order to prevent plastic waste from polluting oceans and rivers.

We for Recyclate shows how a functioning circular economy for used plastic succeeds with examples of PET bottles, HDPE packaging, PP caps and many others. In the material recycling process, a used PET bottle will be turned into a new PET bottle, HDPE material will again be made into HDPE packaging and PP recyclate will be used to produce a PP cap. Resources are conserved and the closed loop can be kept going for a long time with low energy expenditures.