Mechanical Recycling

“Plastic could be one of the most ecological materials of our time if we learn to handle it properly.”

Reinhard Schneider in his acceptance speech at the German Environmental Award ceremony 2019

Advantages of Plastic

Plastics are materials with properties and chemical composition that do not exist in Nature; they are produced by people. The word “plastic“, which means something soft, malleable, capable of being shaped, is derived from the Latin plasticus.

Today we can no longer imagine a life without plastic even though the success story of this practical material is not at all old. Plastics we know and use these days have been around for about 150 years. The mass production of polyethylene (PE), polypropylene (PP) and polyethylene terephthalate (PET) began in the mid-20th century. These materials changed many industries and created the basis for today’s ubiquitous use.

Plastic has many advantages. Lightweight and break-resistant, it is malleable too and can be molded into almost any shape. Furthermore, plastic protects from environmental factors such as heat, light and weather. All of those advantages make plastic an ideal material for the packaging of laundry detergents and cleaning products.

Incorrect Handling – Problematic for the Environment

With the steep increase in the worldwide prodution of plastics since the 1960s, the polluting of our planet with plastic has climbed drastically. Some 6.4 million tonnes of plastic waste make their way into the world’s oceans every year, according to the United Nations Environment Programme (UNEP). The floating litter includes plastic bags, cups, beverage containers, canisters and caps, torn fishing nets and rope, along with running shoes and flip-flops. Other estimates say as much as eight million tonnes pollute the seas per year.

On a more easily understood scale, those numbers translate into a garbage truck dumping a load of plastic waste into the ocean every minute. If nothing is done to counter this trend, we can expect four truckloads per minute by the year 2050. At that point, researchers have said, more debris than fish (by weight) will be swimming in the oceans.

The Solution: Keep Plastic in a Closed Loop

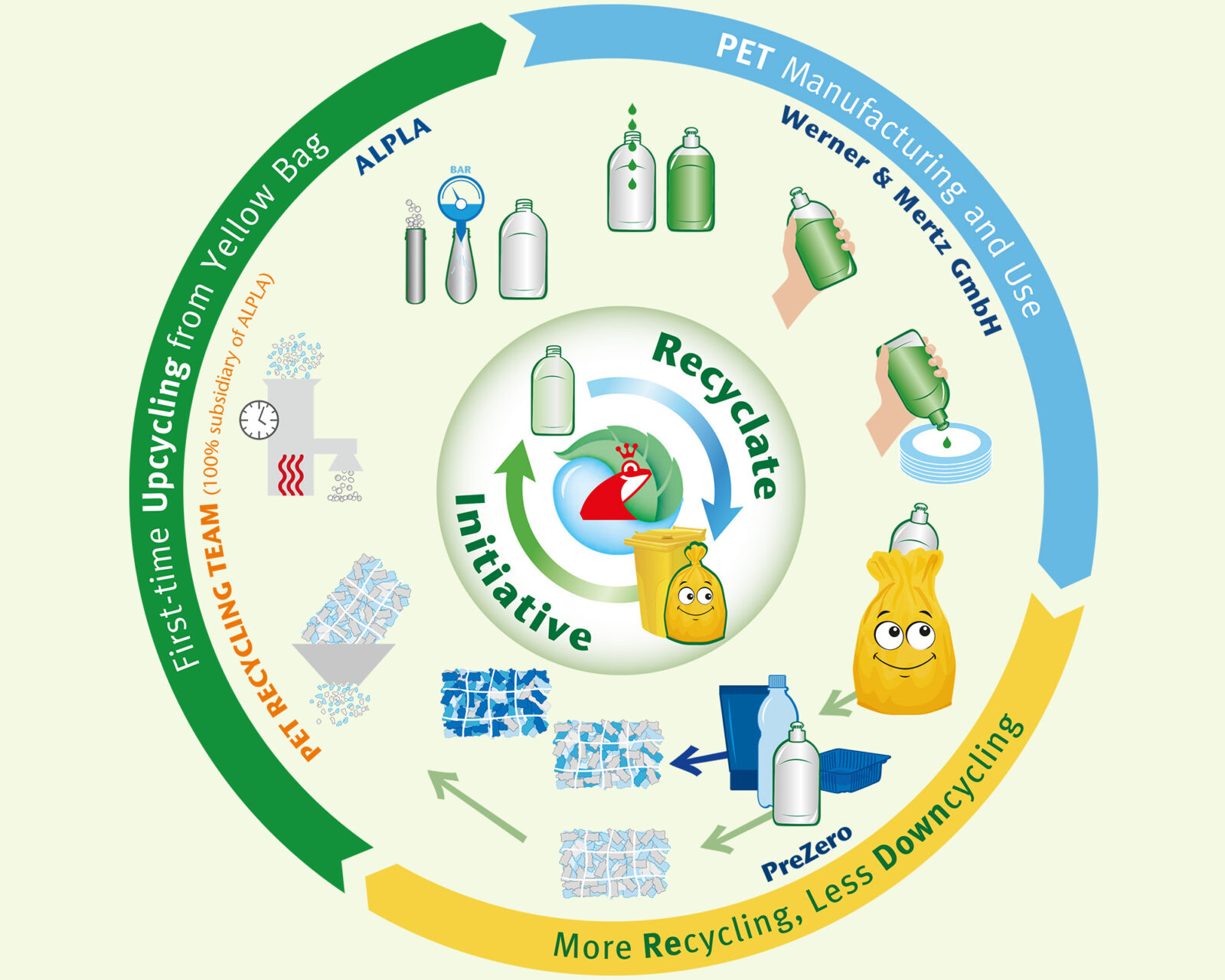

Plastic can be more environmentally friendly than many other materials—if we handle it properly. In 2012 the Recyclate Initiative from Werner & Mertz began promoting a solution, that is, the high-quality reuse of plastic obtained through mechanical recycling. As a collection system for such packaging, the Yellow Bag is the source from which We for Recyclate obtains its raw material for new packaging. With help from cooperation partners along the entire value chain, plastic from the Yellow Bag goes through energy-saving, climate friendly processing and then is turned into new high-quality packaging. The plastic remains in a closed cycle and the environment benefits in two ways. Pollution on land and in the ocean is prevented and natural resources are conserved because there’s no need to produce more new plastic.

And it works. Since the beginning, the Recyclate Initiative has put millions of bottles from the mechanical recycling loop on the market and thereby proven that high-quality recycling of plastic is feasible.

True Recycling vs. Recycling Myths

Because plastic has a low melting point, it is suitable for new uses again and again. Mechanical recycling of plastic is the most direct and energy-efficient form of the circular economy in our industry.

In a 2022 study by ETH Zürich, researchers found that twice as much fossil fuel is burned for plastics production as the amount of oil contained in the plastic feedstock.

The results are so alarming because previous research had concentrated on the environmental pollution that occurs with the disposal of plastic. Those damages alone are enormous. The incineration of plastic packaging, the primary means of disposal in Germany and other European countries, generates on average three grams of CO2 for every gram of plastic. Moreover, burning the plastic is a tremendous waste of a valuable raw material.

The fact that the manufacture of new plastic generates even more GHG emissions than incineration means the carbon footprint of virgin plastic is much worse than previously assumed. Researchers attributed the size of the footprint to the steadily increasing use of coal-generated electricity in production.

That is the case in booming plastics production in emerging economies, such as China, Indonesia and South Africa, where the required energy for new plastic comes from climate-damaging coal-fired power plants. The study notes that many EU countries and Western industrialized countries have outsourced the energy-intense manufacturing of plastic to those countries.

To the study: Growing environmental footprint of plastics driven by coal combustion | Nature Sustainability

New plastics are manufactured mainly with natural gas and crude oil. However, because fossil-based raw materials are becoming scarcer and their use and disposal are harmful to the climate, the use of plastics made of renewable resources is today the subject of research and discussions.

We for Recyclate advocates environmentally friendly handling of plastic. Based on the current state of knowledge, we – and a large number of environmental researchers – see no ecological advantage in the use of plastics of renewable raw materials or biologically degradable plastics. They do not solve the problems with the climate or with the increasing amount of waste that makes its way, uncontrolled, into the environment. We are convinced that only a genuine circular economy can conserve raw materials, protect the environment and prevent waste.

As a solution to the problem of marine pollution, the suggestion has often been made that the plastic trash should be fished out of the ocean and then recycled to make packaging. Unfortunately, it’s not as easy as that. According to calculations made by the Leibniz Centre for Tropical Marine Research (ZMT), only five percent of plastic trash can be recovered from the ocean. Too little to make a real difference. And the little bit of marine plastic that can be collected cannot be recycled. For when plastic is exposed to all kinds of weather for a long period of time, the quality of the material degrades so much that the plastic can no longer be recycled.

To prevent large amounts of plastic from collecting in the ocean year after year, conditions on land have to improve. A functioning circular economy makes a difference. Recyclable packaging and the use of recyclate can contribute greatly to reducing plastic waste. That’s the only way to stem the tide of plastic right at its origin. The initiative We for Recyclate has shown for many years that a closed system of production, usage and material recycling of plastic packaging is feasible.

The many variations of pyrolysis—also known as “chemcycling” or “chemical recycling”—have one thing in common. They require a lot of energy to obtain plastic from pyrolysis oil. The used plastic is decomposed into its petrochemical components at temperatures up to 1,500 degrees Celsius so that it can be processed into plastic again with help from new oil. A study by a major environmental organization documents the poor track record of this process. To convert one metric ton of used plastic into plastic, pyrolysis needs one metric ton of fossil fuel as an additional energy supplier. Independent experts therefore see pyrolysis not as a variety of recycling, but rather as a variant of incinceration.

This source does not protect the climate. Every gram of incinerated plastic generates about three grams of CO2. On top of that, a large quantity of material is lost to pyrolysis. In most cases, the small amount of pyrolysis oil obtained can be processed further only after additional, time-consuming chemical cleaning.

To the study: Understanding the Environmental Impacts of Chemical Recycling – EEB – The European Environmental Bureau

“We see this type of upcycling as actively pursued eco-effectiveness,” says Reinhard Schneider. For the future too the Initiative is working toward meeting ambitious recycling goals. “We want to exploit further the great potential of plastic waste from the Yellow Bag,” Schneider says. “We also are committed to using new technologies. Crude oil is a finite resource and we offer millions of proven examples for an effective recycling loop. Our intention with this practiced circular economy is to embed the general idea of sustainability in consumer awareness.”

The following studies, which Werner & Mertz commissioned, deal with the potential of mechanical recycling for a functioning circular economy and active climate protection.

Werner & Mertz – Beiersdorf – Fraunhofer Institut: How to Evaluate Post-Consumer Polyolefin Recyclates in Cosmetic Packaging?

Oeko-Institut – Compare and contrast of different recycling processes with regard to their costs and benefits

Systemiq – Werner & Mertz wo mechanisches Recycling zur neuen Norm gemacht wird